Cap Inspection – IT 700

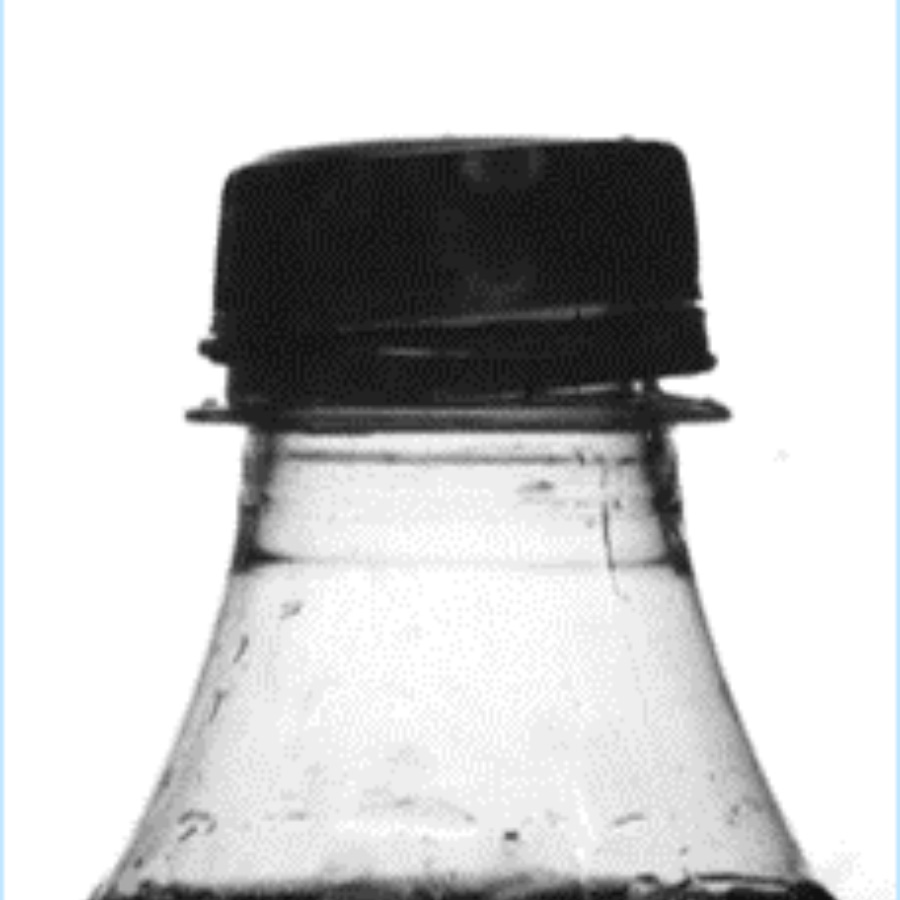

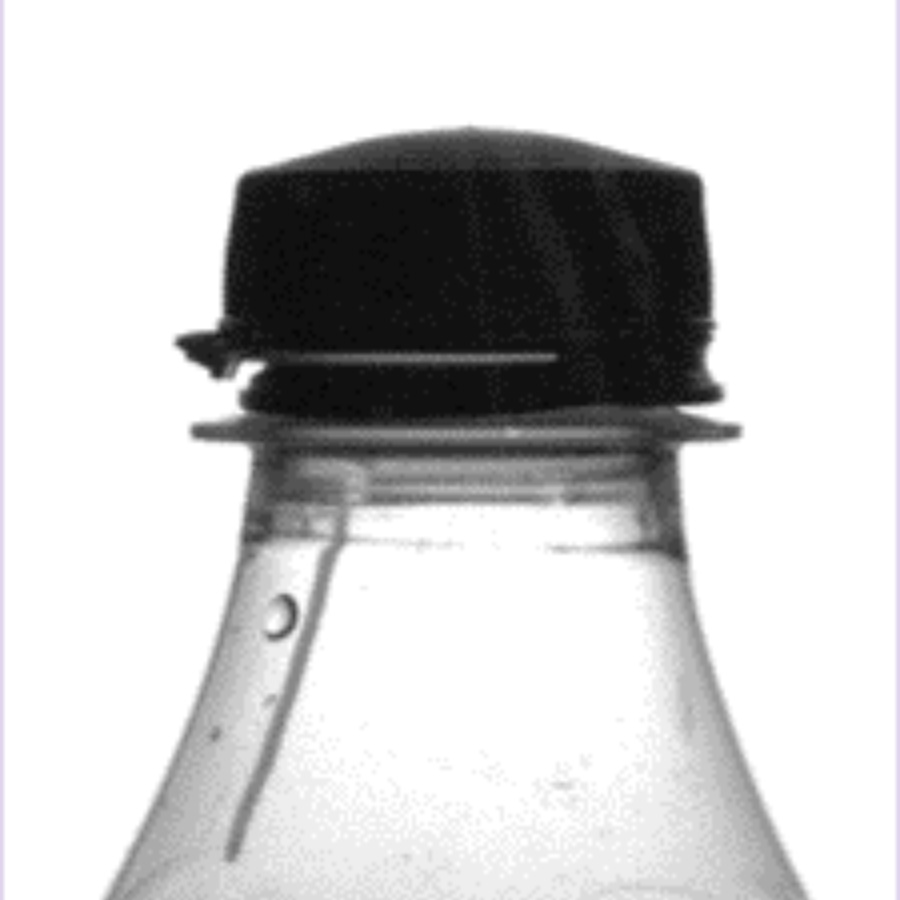

The IT700-IoT is a cap inspection system designed to ensure the quality and conformity of capping. The inspector can detect every defect of the caps. It prevents market claims due to incorrect closure of filled containers, distribution of products not intact, for example, bottles not correctly sealed, breakage of the security ring, or non-compliant/incorrect printed logo on the cap or lid.

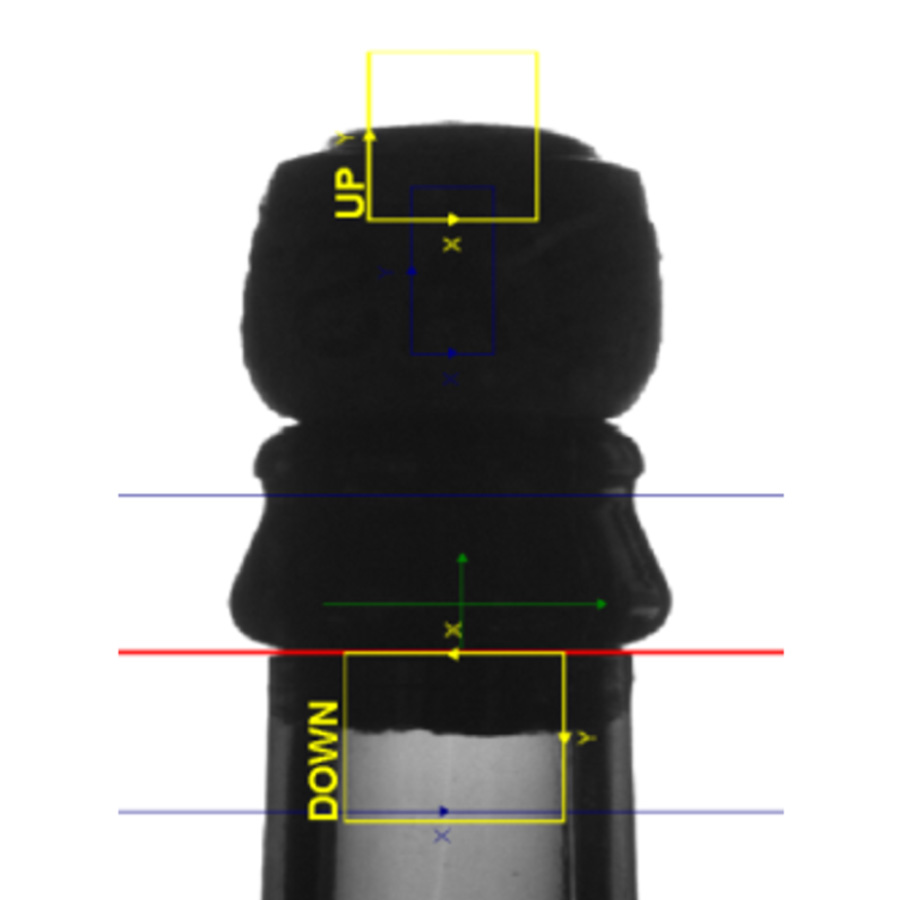

Software tools specific for: FLAT, TETHERED, SPORT-CAP, CORK, MASHROOM and ROPP

- Presence

- Product Compliance

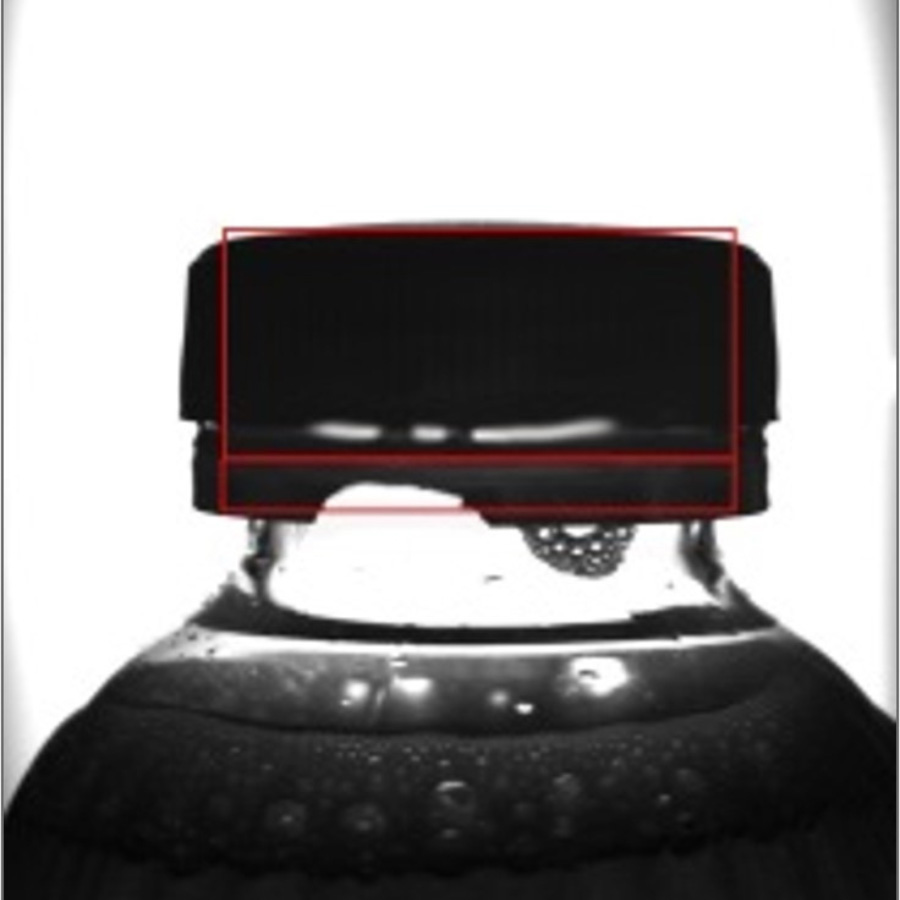

- Integrity

- Positioning

- Security ring integrity

- Missing tamper band

- Damaged tamper band

- Artificial vision

- Configurable from 2 to 5 cameras (including brand inspection)

- Tethered cap configuration

- Water drop compensation

- Integrable in machine or stand-alone

- Production records and pictures storage

- Expandable with other inspections

- User-friendly interface

- Increase production efficiency

- Correct cap application

- Brand protection

- IT 700-IoT

- IT 700-IoT with 4 cameras