In-line 02 concentration wine – PCS 700

The in-line oxygen concentration inspection monitors oxygen and pressure in the bottle’s headspace to monitor the inerting systems’ functionality and avoid oxidation’s negative consequences. The presence of oxygen in the bottle’s headspace causes variation in organoleptic characteristics (colour, taste, etc.) and quality reducing the product’s shelf-life. The measurement is based on an innovative application of laser spectroscopy. It uses a particular physical property of specific molecules in the gaseous state, i.e., the ability only to absorb light at particular wavelengths. This enables the measurement of the oxygen concentration and the pressure inside closed containers quickly and accurately. The laser beam, placed at the correct height on the production line, passes through the bottle in the product-free headspace, making it possible to determine the oxygen concentration and pressure at the speed line. Continuous monitoring of the production process facilitates immediate intervention in case of inefficiencies, avoiding the faulty bottling of large quantities of wine that affects the quality and organoleptic characteristics.

- Oxygen concentration measurement

- Internal pressure

- Laser spectroscopy based

- Non-destructive testing

- High reliability

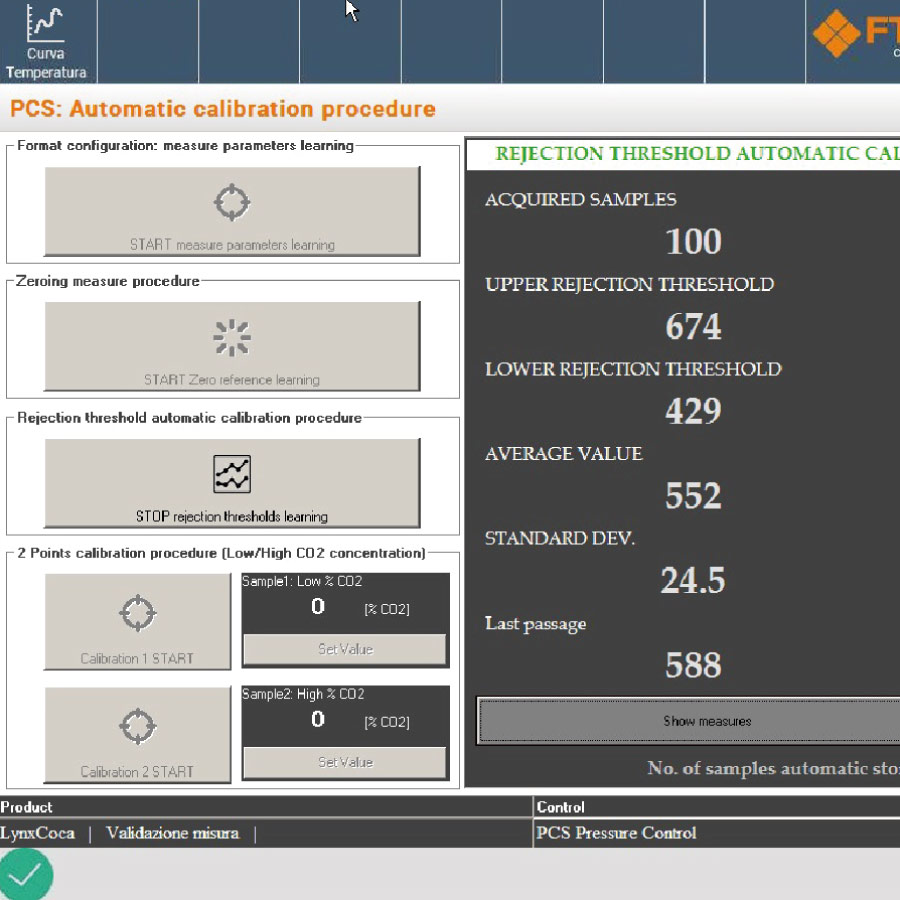

- Wizard software for easy set-up

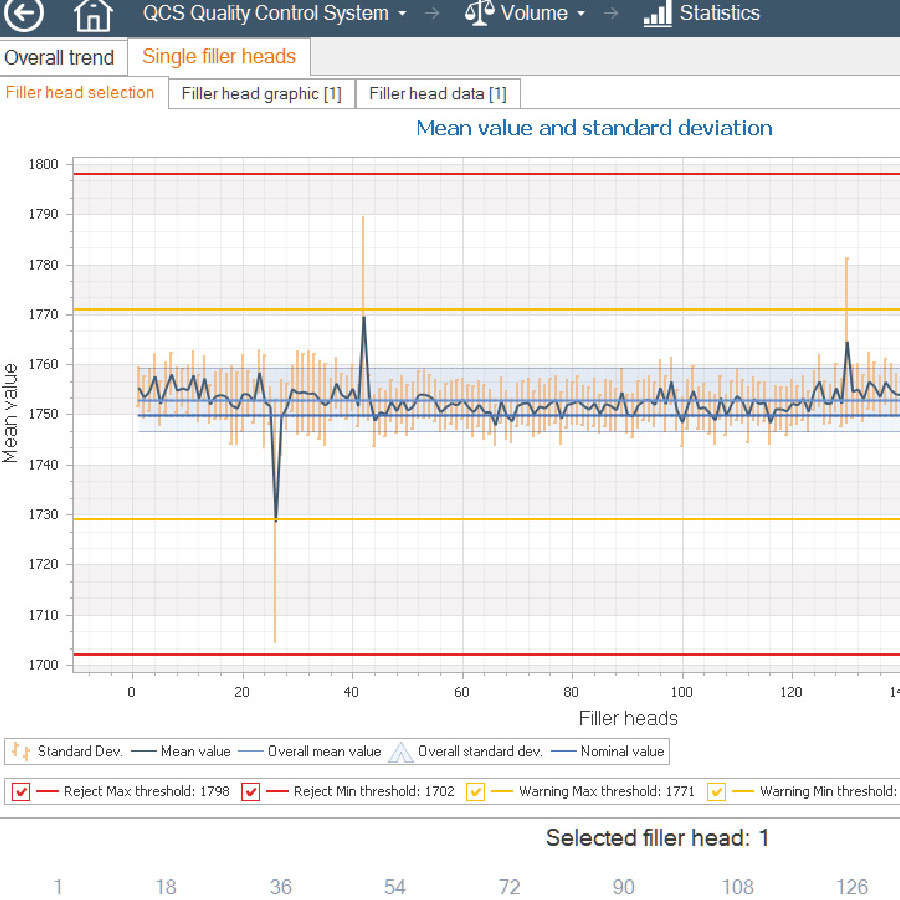

- Production records

- Expandable with other inspections

- User-friendly interface

- Monitor the oxygen concentration in each bottle and the functionality of inerting systems

- Guarantee the quality and shelf life of the product

- Prevent claims from the market

- Consumer satisfaction

- PCS 700 O2